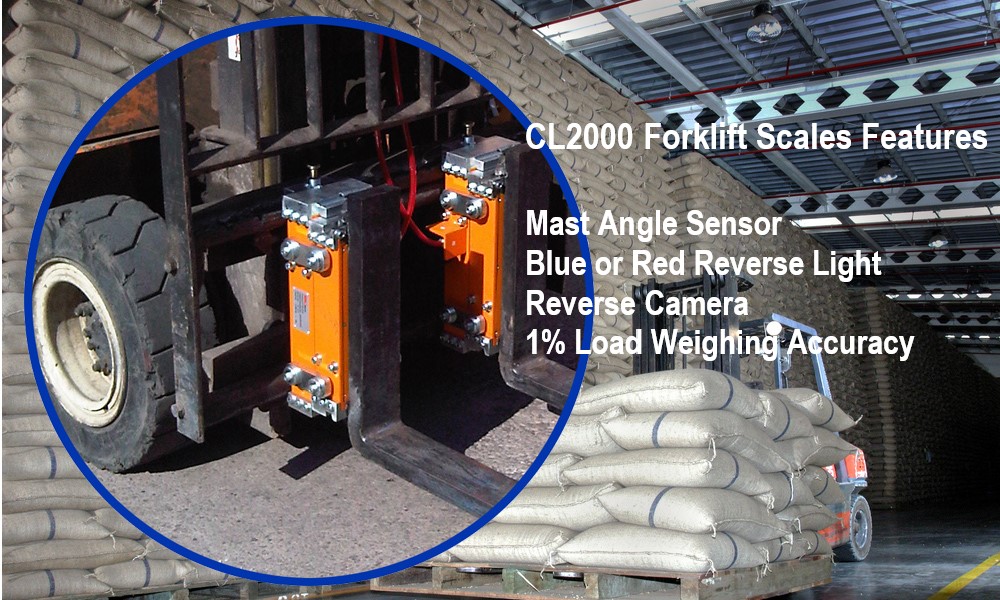

Compuload CL2000 Forklift Weighing System

Added Features

The Compuload CL2000 Forklift Weighing System is a ergonimically designed weighing system built to incorporate multiple safety features into 1 system these are detailed below.

- Mast Angle Sensor – Displayed on the bottom of the screen , the angle of the mast will be displayed to assist the driver to determine if the forks are flat when placing products on high racking, or if entering pallets on high racking , reducing the risk of dragging or pushing the pallet whilst on the racking. Will also assist when entering products that can be damaged such as bulka bags for example.

- Blue or Red Reverse Light. – When the forklift is in Reverse, the Blue or Red Light shines normally around 3 metres behind the forklift on the floor. This assists workers identify when the fork is reversing from between racking or around corners.

- Reverse Camera – When the forklift is placed in Reverse, the display will revert to a Camera display from the reverse camera.

Compuload CL2000 Forklift Weighing System Product Description

- Unrivalled Accuracy (within 0.1% of weighing capacity)* than existing hydraulic based system.

- Proven durability and ruggedness – high resistance to shock, frequent knocks and impacts in harsh industrial environment.

- Minimum maintenance when compare to other forklift scales in the market.

- Simple latch on design and very easy installations.

- No modifications needed on existing forklifts.

- Available in various models for hook type forklifts with standard carriage class II, III and IV for 2.5, 4.5 and 7 ton forklifts.

- Customisation possible for other types of forklifts design.

- Choice of indicator display’s depending on your weighing application from basic to advanced data storage management with printer & down-loader options

* Note: assumes forklift is on level surface

Our Compuload LCFS system stands on its own exceptional and demonstrated merits of accuracy, ruggedness and versatility (user-owned forks, attachment compatibility and quick easy re-location of the scale if the forklift fails.)

Our product reduces industrial weighing operations time by at least 50%. The Compuload LCFS forklift scale has been designed to maintain high accuracy and durability even in harsh industrial environment, proven by both local and overseas customers.

A reliable forklift weighing scale will benefit any operations involving materials handling. For example, incoming raw materials and outgoing products checking, chemical dosing/metering directly from IBC/drums, stock taking, warehouse management and logistics, just to name a few.

Specifications, Dimensions & Load Ratings

| Model No. | Forklift Carriage Class | Carriage Bar Spacing (H) | Loads Rating |

| SK16 | Class II | 40.6cm (16”) | Up to 2500kg (5550lbs) |

| SK20 | Class III | 50.8cm (20”) | Up to 4500kg (10000lbs) |

| SK25 | Class IV | 63.5cm (25”) | Up to 7000kg (15500lbs) |

The Compuload CL2000 Forklift Weighing System weighing modules are the core components of the forklift weighing system. The Compuload LCFS weighing modules have been specifically designed to meet all essential criteria for retrofit forklift weighing systems.

Compuload LCFS consists of two weigh assemblies, which fit side by side directly on standard forklift carriages.

The Compuload LCFS concept is very simple:-

- Simply remove the existing forks from the carriage.

- Hook the Compuload LCFS modules on the carriage.

- Hook the existing forks back on to the front of the Compuload LCFS modules.

The Compuload LCFS design is extremely robust and has fully protected electronics contained inside the mechanical assemblies. Our patented design has its unique and proven advantages over conventional instrumented forks.

Get in touch